PT. DMC TEKNOLOGI was established in June 1996 as DMC’s overseas manufacturing facility. While our primary production has long focused on resistive touch screens, we began manufacturing capacitive types in 2022. Leveraging our status as a Bonded Factory, the majority of our products are exported not only to Japan but also to the EU, North America, and other Asian countries.

DMC was established in 1973 as a manufacturer of art materials for printed circuit boards used in televisions, computers, and other electronic devices. Since shifting its focus from materials to touch screen technology in 1991, DMC products have been used worldwide. Today, touch screens have become an essential part of the devices we use in our daily lives, including personal gadgets, PCs, and smartphones. In addition, machines, ATMs, medical equipment, POS/KIOSK systems, and other industrial tools have also adopted touch screen technology. DMC products are primarily utilized in these sectors. As the IT industry continues to advance, the adoption of touch screens is expected to grow even further.

To meet the anticipated growth of this market, DMC has established a high-mix, low-volume production system that prioritizes long-term stable supply. To meet market demands, various types of touch screens are available globally. However, two main types are commonly used in our daily lives and business environments. One is the resistive type, widely adopted across many industries. The other is the capacitive touch screen, which has seen rapid market growth due to the widespread use of smartphones.

DMC offers both types of touch screen technologies. We have a long-standing history with resistive touch screens, known for their exceptional quality. While leveraging our expertise in resistive technology, we have also established a capacitive touch screen production line in response to rapid market growth. We are committed to supporting customers with diverse and fast-changing needs. In light of global uncertainties such as pandemics, conflicts, and climate change, the importance of Business Continuity Planning (BCP) is increasingly being recognized. In fact, DMC’s factory in Fukushima sustained significant damage during the 2011 earthquake disaster. However, even under such extreme conditions, we never compromised on “Stable Supply.” This resilience is further strengthened by our Indonesian plant, PT. DMC TEKNOLOGI INDONESIA, which is fully supported by our operations in Japan.

Our factory network is strategically mapped to spread risk and prevent critical disruptions, ensuring uninterrupted procurement for our customers. DMC exports nearly half of its total production to major countries across Europe, Asia, and North America. We have built trusted relationships with customers in these markets by consistently ensuring a stable product supply. We remain committed to maintaining a reliable system that supports business continuity and strengthens both domestic and international supply chains to meet our customers’ evolving needs.

Sustainable Efforts in a Growing Market

Sustainable Efforts in a Growing MarketDMC was established in 1973 as a manufacturer of art materials for printed circuit boards used in televisions, computers, and other electronic devices. Since shifting its focus from materials to touch screen technology in 1991, DMC products have been used worldwide. Today, touch screens have become an essential part of the devices we use in our daily lives, including personal gadgets, PCs, and smartphones. In addition, machines, ATMs, medical equipment, POS/KIOSK systems, and other industrial tools have also adopted touch screen technology. DMC products are primarily utilized in these sectors. As the IT industry continues to advance, the adoption of touch screens is expected to grow even further.

To meet the anticipated growth of this market, DMC has established a high-mix, low-volume production system that prioritizes long-term stable supply. To meet market demands, various types of touch screens are available globally. However, two main types are commonly used in our daily lives and business environments. One is the resistive type, widely adopted across many industries. The other is the capacitive touch screen, which has seen rapid market growth due to the widespread use of smartphones.

DMC offers both types of touch screen technologies. We have a long-standing history with resistive touch screens, known for their exceptional quality. While leveraging our expertise in resistive technology, we have also established a capacitive touch screen production line in response to rapid market growth. We are committed to supporting customers with diverse and fast-changing needs. In light of global uncertainties such as pandemics, conflicts, and climate change, the importance of Business Continuity Planning (BCP) is increasingly being recognized. In fact, DMC’s factory in Fukushima sustained significant damage during the 2011 earthquake disaster. However, even under such extreme conditions, we never compromised on “Stable Supply.” This resilience is further strengthened by our Indonesian plant, PT. DMC TEKNOLOGI INDONESIA, which is fully supported by our operations in Japan.

Our factory network is strategically mapped to spread risk and prevent critical disruptions, ensuring uninterrupted procurement for our customers. DMC exports nearly half of its total production to major countries across Europe, Asia, and North America. We have built trusted relationships with customers in these markets by consistently ensuring a stable product supply. We remain committed to maintaining a reliable system that supports business continuity and strengthens both domestic and international supply chains to meet our customers’ evolving needs.

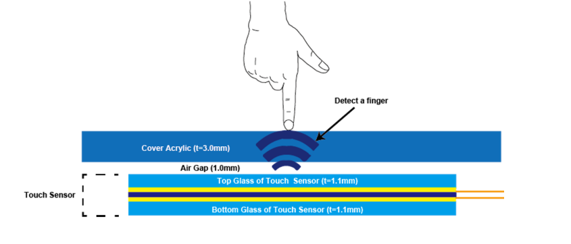

Touchscreens, as we call them, always consist of some layers. LCD, Touchscreen(sensor), and Cover Glass/Overlay Film. These components are originally separated. DMC manufactures this 'Touchscreen sensor" layer which detects our physical contact operation. DMC is an expert in traditional analog resistive type touchscreen. Additionally, projective-capacitive touchscreens which have the same structure as mobile phones are also provided as industrial-grade product.

We're located in one of the ASEAN countries. Shortening transport distance is the first advantage. In addition, we benefit your sourcing in tax benefits, customs process, etc. Due to the current world affairs, more and more end-customers are likely to choose components with the origin of this region.

Semua material yang masuk harus melewati pemeriksaan masuk.

Untuk beberapa proses, inspeksi visual diperlukan sebelum melanjutkan ke proses berikut.

Di jalur produksi dan fase keluar, kami memeriksa fungsi kelistrikan.

Sebelum dikirim dilakukan uji kehandalan agar keawetan produk terjamin.

Contributing to the creation of a happier society by supporting the growth of dream-driven enterprises — this is our mission.

Usco Co., Ltd. was established to support the growth of dream-driven companies. While society continues to evolve, the purpose of our activities has remained unchanged since the beginning: to foster the development of companies with vision and to promote both the material and emotional well-being of the people who work there. We remain committed to working hand-in-hand with our customers to create a brighter tomorrow through ever-improving services.

As the holding company of the group, Usco Co., Ltd. supports the development of two core businesses—automotive and electronics—through its management support services. In addition, we strengthen the group through oversight and strategic alliances with companies that share our vision.

As the holding company of the group, Usco Co., Ltd. supports the development of two core businesses—automotive and electronics—through its management support services. In addition, we strengthen the group through oversight and strategic alliances with companies that share our vision.

Kawasan Industri Jababeka II, Jalan Industri Utama Blok RR7, Pasirsari, Cikarang Selatan, Bekasi – Jawa Barat 17550

One of the medical device manufacturers ordered our touch screen products by providing specifications for us to produce the touch screens. These will be applied in their medical products, replacing imported components with locally sourced ones.

One of the medical device manufacturers ordered our touch screen products by providing specifications for us to produce the touch screens. These will be applied in their medical products, replacing imported components with locally sourced ones.

Our touch screens are "Designed in Japan & Made in Indonesia." With over 25 years of experience, we have proven our reliability and quality. We ensure that our customers become more dependable in the fast-paced technology industry. For our customers in ASEAN, we provide direct support from Indonesia to optimize their QCD (Quality, Cost, Delivery).

1. Ensures an operating temperature range from -40°C to 80°C. This technology is suitable for operation terminals on equipment exposed to prolonged or high extreme temperatures.

2. Impact-resistant solution. DMC's projected capacitive touch controller can detect touch through glass or acrylic covers by enhancing sensitivity.

3. Designing glass structure materials with a unique ability to absorb UV rays. This structure is used for the adhesive layer between the glass layers of the projected capacitive touch screen, helping to reduce the impact of UV rays on the LCD beneath the touch screen.

The company continues to provide customer service even after the purchase and product application, ensuring ongoing cooperation. Technical support is available in case of any issues — the problematic product will be analyzed, and improvements will be made to prevent similar issues in the future. Product usage information and online assistance are also provided.

Minimal order 1 pcs :